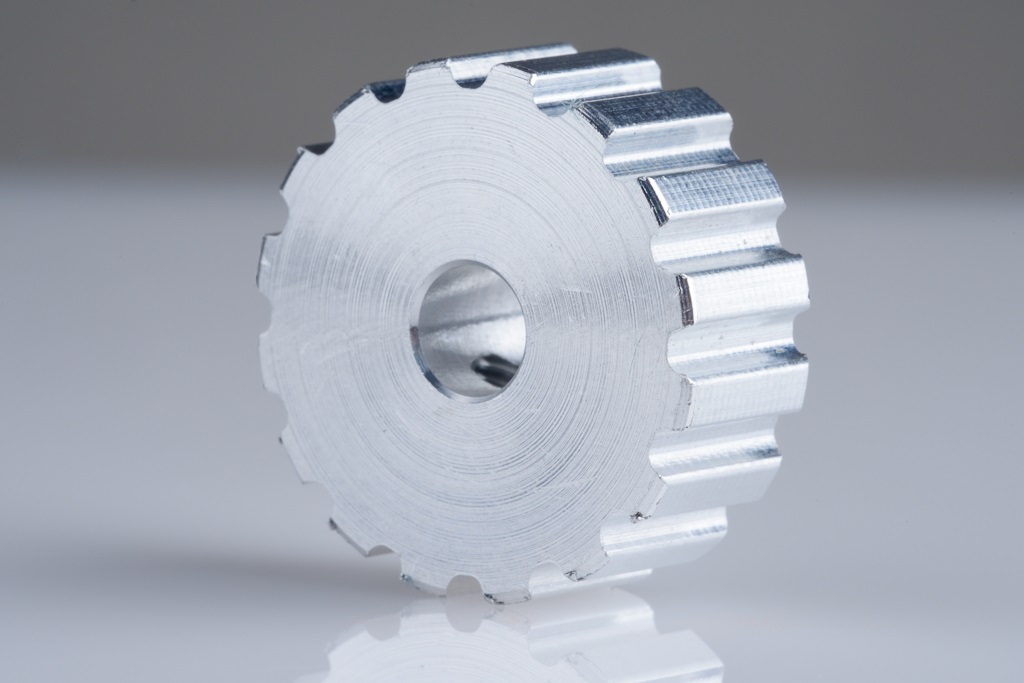

PULEGGE DENTATE

Tornomatic supporta il cliente per rispondere alle esigenze di pulegge dentate con profili a richiesta.

Tutte le nostre lavorazioni possono essere eseguite sui seguenti materiali: bronzo, ottone, alluminio, delrin e altri materiali plastici, tela bakelite, acciai inox, ferrosi e legati.

Torneria mono e bimandrino

- Diametro max da barra 74

- Lunghezza massima 600/800

- Barre tonde e profilati (quadri, esagoni e speciali)

- Fresature in macchina, fori trasversali …

Torneria plurimandrino

- Diametro min. 5 e max 38

- Barre tonde e profilati (quadri, esagoni e speciali)

- Fresature in macchina, fori trasversali …

Lavori di ripresa e finitura

- Riprese di foratura, fresatura, alesatura, filettatura in automatico.

- Assemblaggi, tornitura da ripresa, foratura, alesatura, fresatura, stampigliatura, tranciatura, rullatura di filetti, godroni e viti senza fine, lappatura, rettifica tondi e spallamenti, brocciatura di fori cilindrici, chiavettati e profili vari, rifinitura tramite vibro finitura.

- Lavorazioni varie su centri di lavoro verticali ISO30 con cambio utensile rapido (2" Truciolo-truciolo)

Dentatura

- Dentatura fino a modulo 3 di ingranaggi e 5 di Viti senza fine

- Diametro massimo mm130

- Dentatura ingranaggi cilindrici a denti diritti ed elicoidali, viti senza fine...

- Skiving e Pre-Skiving fino a modulo 3